Reduce nitrite/nitrate levels

Reduce nitrite/nitrate levels

The health effects of nitrite and nitrate in meat products have been intensively discussed for a long time. By using food cultures, the amount of nitrite in meat products can be significantly reduced or even completely replaced. Producers can learn here how this can be achieved.

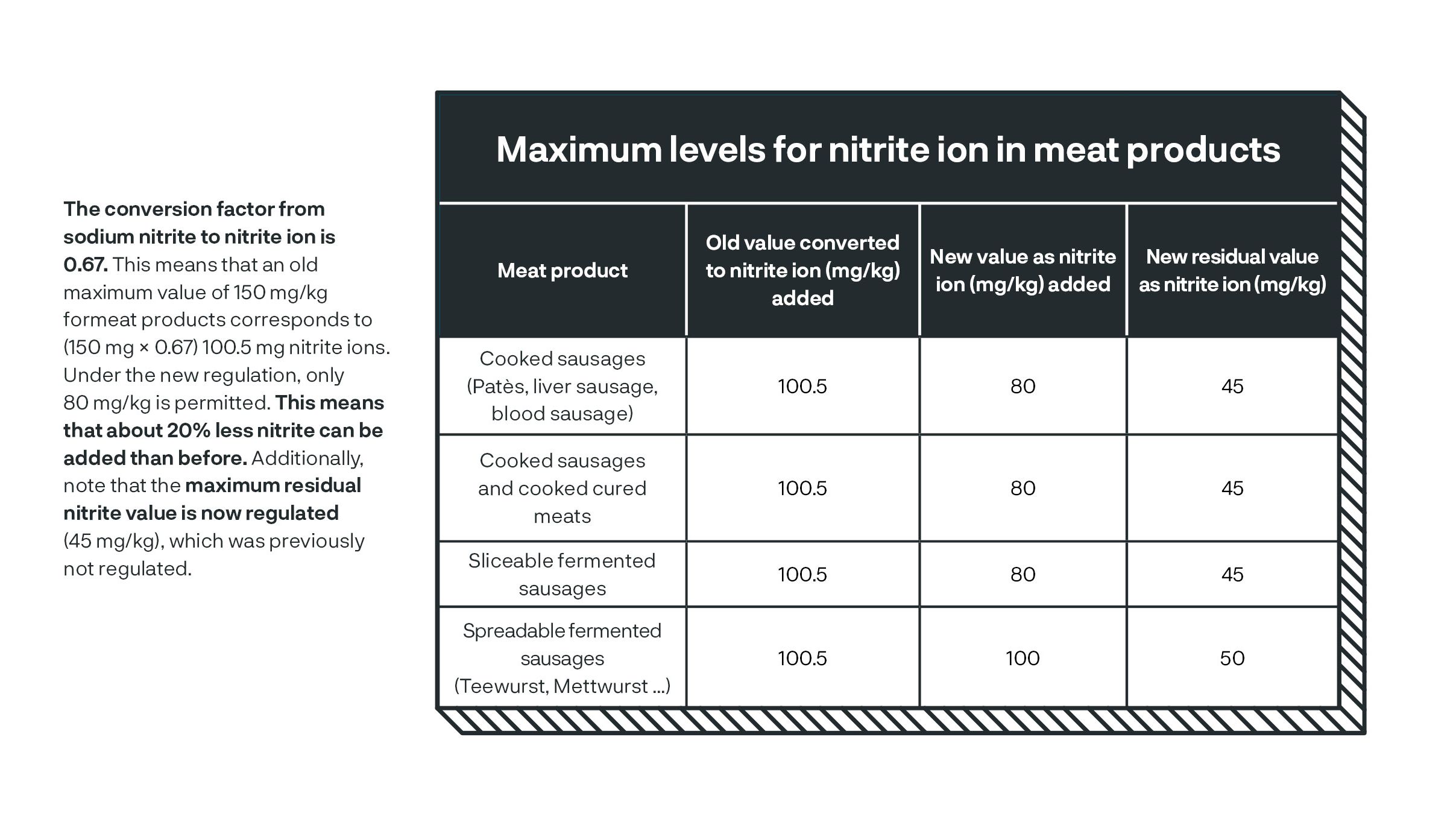

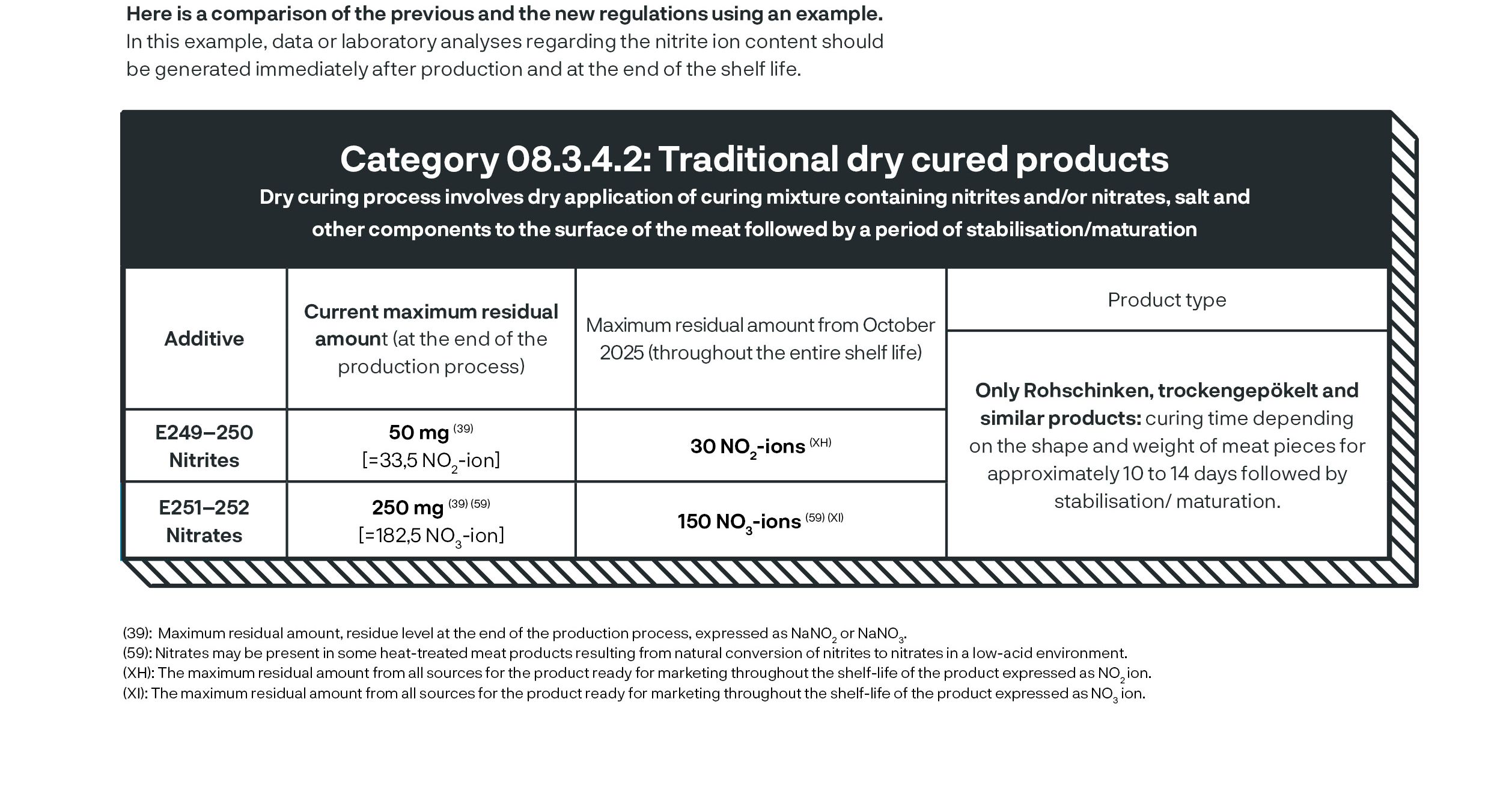

With the amending Regulation (EU) 2023/2108, the European Commission adapted the maximum level regulations for nitrite and nitrate in selected food categories in autumn 2023. The permissible application quantities for nitrites (E 249, E 250) and nitrates (E 251, E 252) were reduced. The transitional period ended in October 2025, so the regulation must now be complied with.

What is newly defined?

In addition to the maximum quantities used, maximum quantities for residual nitrite and nitrate values up to the best-before date are now also regulated. The residual amounts of nitrites and nitrates are now expressed as a corresponding molecular ion and can be easily converted from the previous specifications as sodium nitrite or sodium nitrate by means of a factor. The changes apply throughout the entire shelf life until the end of the best-before date, whereas previously only the values at the end of the production process were decisive.

What are the challenges?

In the case of products with closed circuits without cooking or drying loss, such as cooked sausage and cooked ham in closed casings, it is easier to adjust or control the residual quantities.

Meat products with cooking and/or dry loss due to maturation are more complex. In this case, an external examination is recommended in all cases.

Adjustments in accordance with the maximum quantity regulation

The implementation of the new maximum level regulations must be carried out by reviewing the entire formulation; in some cases, analyses should also be carried out for verification.

How do you implement the maximum quantities?

When determining the residual amount, nitrate or nitrite ions from all sources, i.e. all ingredients used, are taken into account. The consideration includes both obvious sources, such as nitrite curing salt used, and non-additives, such as ingredients that sometimes contain a high nitrate content (e.g. vegetable powder, spices, etc.).

Nitrate contamination of drinking water, which varies from region to region, may also have an effect on the total content in the final product.

Gain experience

For the individual products, empirical values must be generated on the influence of the input quantities (additives, ingredients, water, use of cultures and other raw materials) and the process parameters (ripening time, temperature) on the existing nitrate and nitrite contents.

We recommend appropriate tests with regard to the nitrite and nitrate contents at the relevant time (e.g. end of the production process, beginning and end of the entire shelf life).

What else can help?

For fermented sausage and raw cured meat products, the use of starter cultures supports nitrate degradation and thus ensures lower residual nitrate values.

All our maturing cultures support nitrate reduction.

These cultures are able to convert nitrate into nitrite, which is then chemically converted to NO and reacts with various meat proteins, including stable curing red (nitrosomychromogen).

The starter cultures thus actively contribute to the reduction of residual nitrite and nitrate levels.

In general, it can be said that the new regulations now place responsibility on users and manufacturers to verify compliance with the requirements. Ultimately, a check on the final product and over the entire shelf life is required.

More information about our solutions?

Starter cultures for reducing nitrite and nitrate in raw sausages and cured meats – discover how our solutions support nitrate reduction and significantly lower residual levels.

BITEC COTTO®

Ideal for all those who want to produce cooked cured products and boiled sausage without the addition of nitrite or nitrate - for a natural recipe and conscious enjoyment.