Laboratory

Laboratory

Quality is more than a promise

The world of spices is fascinating: leaves, buds, roots, bark, fruits and seeds from all over the world create unique culinary experiences.

In addition to the very best raw materials, a great deal of experience and the highest standards in production and analysis methods are required to make these experiences possible. These also apply to food cultures, which also contribute to tasty and safe food.

Our customers benefit from the strict criteria set in our in-house laboratories at all NovaTaste Europe locations, which ensure the high quality and safety of our products.

Safety first

All goods (spices, herbs, vegetables and active ingredients) are digitally recorded by us and so it is already clear what needs to be done upon delivery. Individual, risk-based test plans with up to 20 different analysis parameters are defined for the individual raw materials, which are regularly reviewed by the managers of the laboratories and adjusted if necessary. Only after completion of all stored analyses is the release for the respective raw material given. The decision on the use of a product is always assessed and made by one of the highly qualified employees.

Controlled quality

The NovaTaste laboratory in Freilassing has the most extensive analysis capabilities of the group in Europe. There, the focus is on quality control of herbs and spices.

For each of our natural raw materials, specific product risks are minimized by means of individual test plans.

Extensive chemical, physical and microbiological tests in our in-house laboratories also ensure our high quality standards when the raw materials are delivered.

The laboratory in Freilassing offers:

- approx. 200 analysis methods

- the proximity to production, which brings with it the advantage of short distances

- plenty of space for practical work

- a separate area for microbiological examinations

- an authorisation in accordance with the Infection Protection Act for the examination of pathogenic microorganisms

Quality controls Freilassing

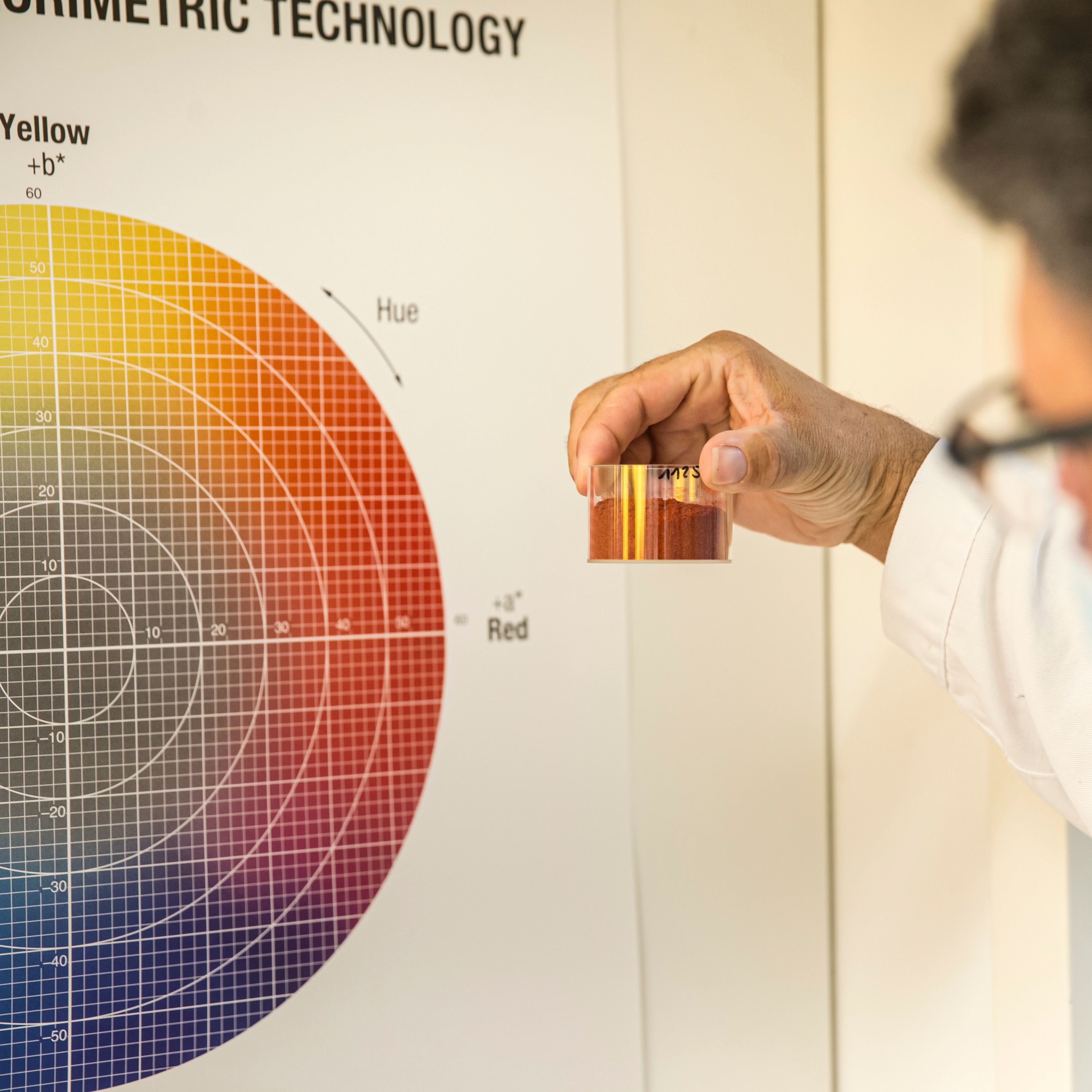

In accordance with our requirements, we evaluate and analyse natural ingredients that determine value and quality, such as:

- flavor components

- pungent substances

- humidity

- purity

Diverse tasks

The employees in Freilassing examine incoming raw materials, support product development at the company headquarters in Salzburg and the branch in Holdorf and process customer-specific enquiries. Every day, samples of incoming raw materials are taken from the incoming goods department. Every release for a raw material is active, which means that nothing is released automatically.

Food cultures put to the test

Our company location in Holdorf is also equipped with a laboratory. In addition to challenge and storage tests for food cultures, we also carry out bioprocess development for our starter culture production in Stuttgart and product development for new food cultures.

Since 2014, we have been operating a state-of-the-art research and development laboratory there, as well as one of the few laboratories in the entire industry with security level 2.

This enables us to research principles for combating pathogenic microorganisms, i.e. pathogenic bacteria, and to test existing food cultures with protective characteristics for their effectiveness. This area plays an important role in the development of food cultures.

360° thinking at all locations

Regardless of the location, the same applies to everyone: What the employees in our laboratories have to deal with from day to day is unpredictable. For this reason, food chemists, technologists, chemical and dairy laboratory technicians must remain flexible and set their work priorities as necessary.